Products

Get to know our products and find out how each one can guarantee the best performance for your business

-

Select the product

VACUUM DISC FILTERS

BRASFELT Vacuum Disc Filters are equipment used for solid-liquid separation. They can be applied in different processes, and today, the vast majority are installed in iron ore processing plants and are known as the most efficient available in the South American market.

BRASFELT develops low-cost filters that have excellent production capacity, high efficiency in removing moisture and low operating and maintenance costs.

Our task is, based on the data provided by the customer, to dimension the most suitable equipment for the type of operation, guaranteeing the best possible performance.

This equipment is accredited by BNDES – FINAME – Code 3687514.

Slide title

Escreva sua legenda aquiButton

Slide title

Escreva sua legenda aquiButton

Slide title

Escreva sua legenda aquiButton

Slide title

Escreva sua legenda aquiButton

Slide title

Escreva sua legenda aquiButton

Slide title

Escreva sua legenda aquiButton

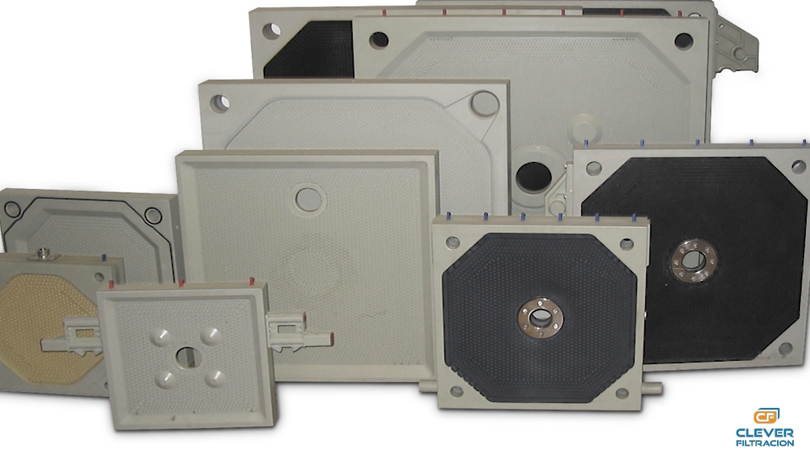

FILTER PRESS

Brasfelt-Fraccaroli & Balzan filter presses are equipment used for solid-liquid separation, whose main characteristic is versatility, allowing its use in different applications, such as steel, metallurgical, mining, chemical and food.

The technology used in our filter presses is the result of an Italian-Brazilian partnership, which brought together the know-how Fraccaroli & Balzan S.p.A., present for more than 54 years in the market, having more than 400 filters installed worldwide, with the experience of BRASFELT Ltda, for more than 30 years providing solid-liquid separation solutions in the Brazilian and Italian market.

-

Keep reading

Currently, the Brasfelt-Fraccaroli & Balzan filter press has been an essential tool in the treatment of tailings and dry disposal, reducing the need for dams.

Brasfelt-Fraccaroli & Balzan filter presses stand out for their robustness, reliability and versatility and can be manufactured according to the needs of each customer:

- Chamber, membrane or mixed plates

- Filter outlet through the side of the plates (individual open type) or via internal circulation through the plates and manifold (closed type plate)

- Manual hydraulic, electric hydraulic or hydro-pneumatic closing system

- Automatic or manual plate displacement, can be done individually or in groups of plates

- Filtration pressures up to 50 bar

- Movement of the plates via lateral or upper bars

- Various possibilities of automatic screen washing

- Retro-washing of the pie

- Cross drying of pies

Slide title

Escreva sua legenda aquiButton

Slide title

Escreva sua legenda aquiButton

Slide title

Escreva sua legenda aquiButton

Slide title

Escreva sua legenda aquiButton

Slide title

Escreva sua legenda aquiButton

Slide title

Escreva sua legenda aquiButton

Slide title

Escreva sua legenda aquiButton

Slide title

Escreva sua legenda aquiButton

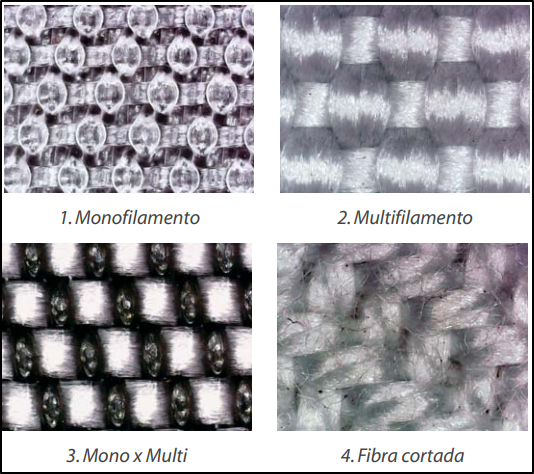

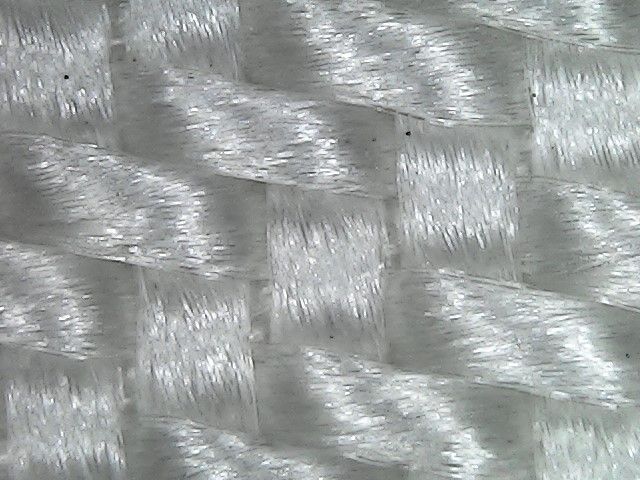

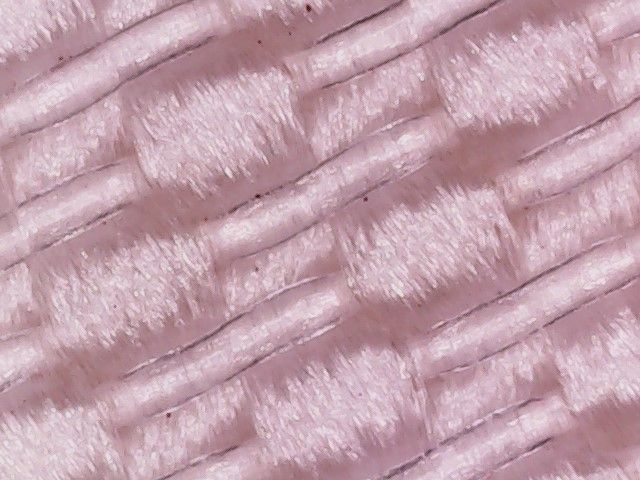

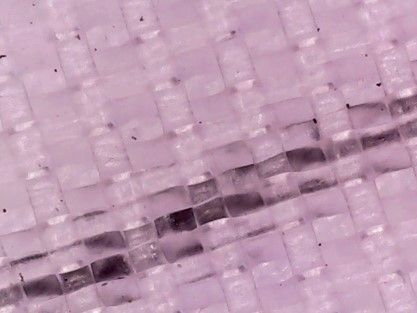

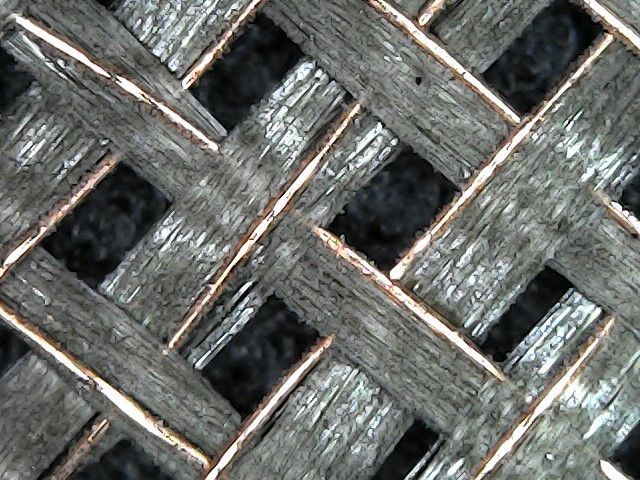

Filter MEDIA

For all wet filtration processes, BRASFELT filter elements are manufactured in order to obtain the best efficiency in terms of solids retention, productivity, lifespan, and, consequently, the best cost benefit. All these factors are directly linked to the filter fabric type.

BRASFELT has a wide range of fabrics, selected in lab tests, case by case, according to the sample of the product to be filtered. Each fabric has its own characteristics, which are important factors for choosing the most suitable one for each filtering condition, including tailings filtration.

Título do Slide

Escreva sua legenda aquiBotão

Título do Slide

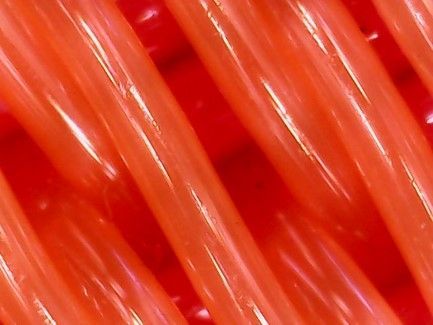

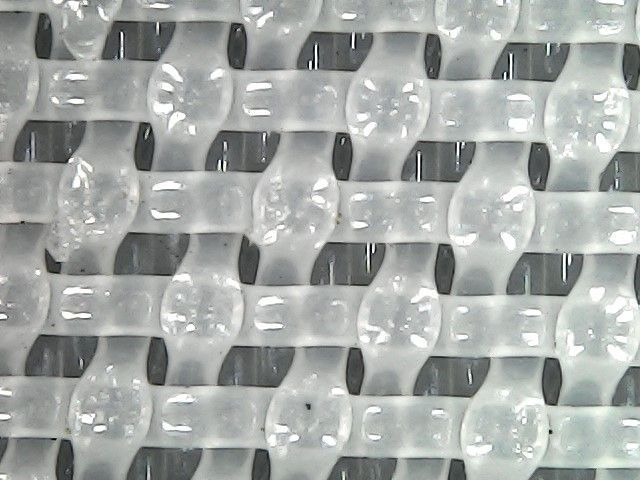

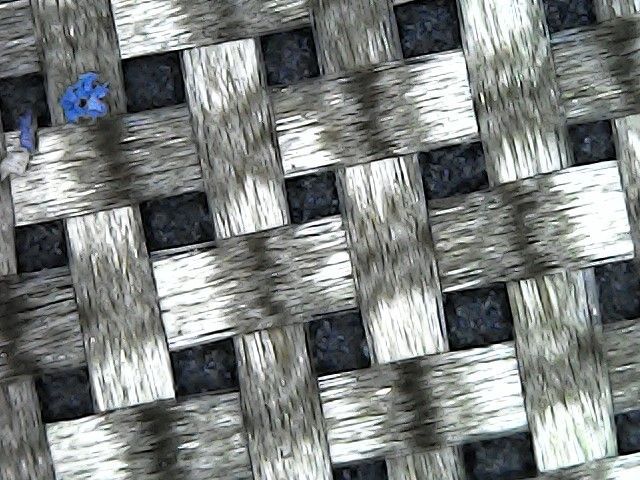

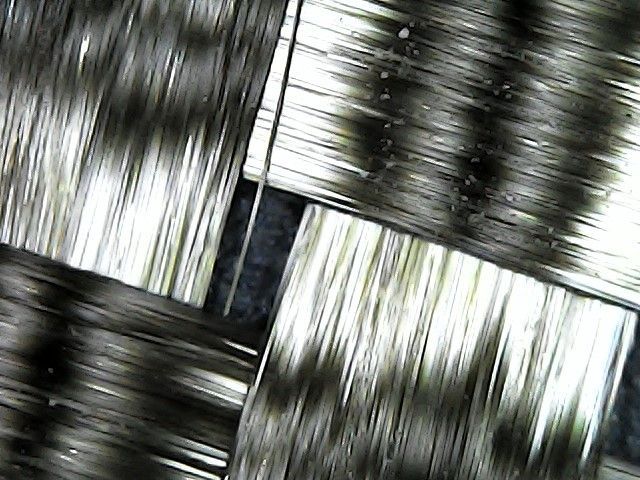

Mono-elastic

Botão

Título do Slide

Mono-elastic

Botão

Título do Slide

Elastic yarn

Botão

Título do Slide

Monofilament used

Botão

Título do Slide

Mono-Multi used

Botão

Título do Slide

Monofilament

Botão

Título do Slide

Mono-Multi

Botão

Título do Slide

Basalt yarn

Botão

Título do Slide

Basalt yarn

Botão

Título do Slide

Multifilament

Botão

Título do Slide

multifilament

Botão

Título do Slide

Mono-Multifilament

Botão

Título do Slide

Monofilament

Botão

Título do Slide

Monofilament

Botão

Título do Slide

Monofilament (used)

Botão

Título do Slide

Monofilament(used)

Botão

Título do Slide

Mono-Multifilament (used)

Botão

Título do Slide

Used Mono-Multi

Botão

Título do Slide

Monofilament

Botão

Título do Slide

Monofilament

Botão

Título do Slide

Monofilament

Botão-

Título do Slide

Multifilament Basalt

Botão

Título do Slide

Multifilament Basalt

Botão

Título do Slide

Multifilament Basalt

Botão

Título do Slide

Filter Press Cloth

Botão

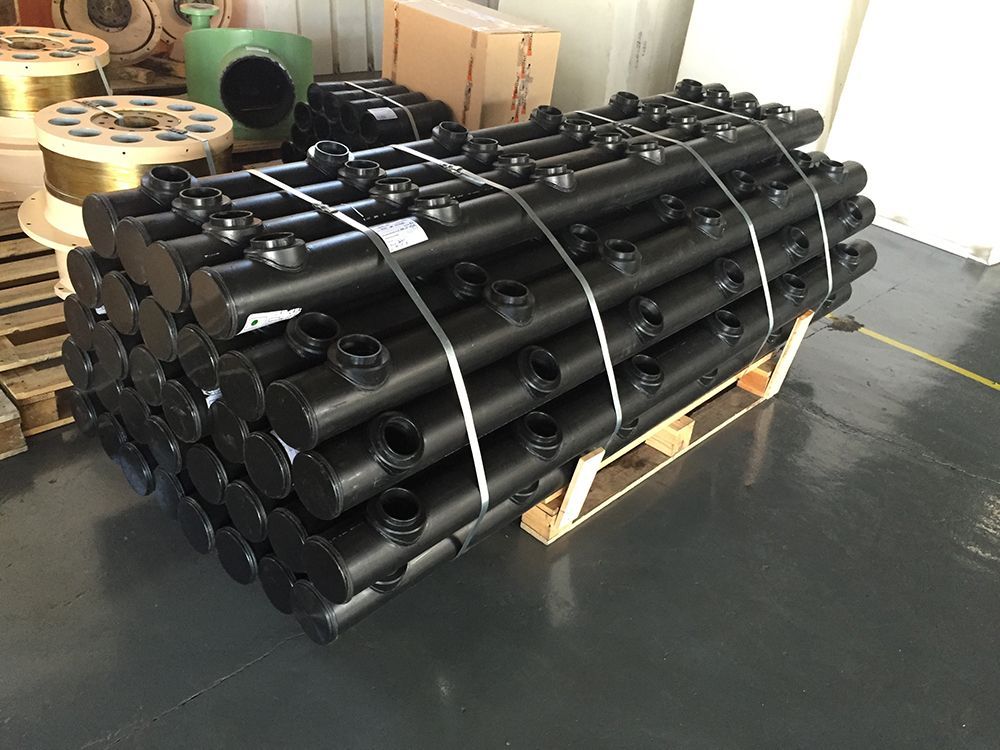

SPARE PARTS

In addition to manufacturing complete equipment, BRASFELT also supplies all spare parts and consumables for the most diverse filters, such as:

-

Vacuum disc filter

- High-density polyethylene (HDPE) and polyurethane filtrate tubes

- Sealing rings

- Deflector plates

- Bearing bushings

- Vacuum control plates

- Vacuum heads (fixed or variable formation zone)

- Wet and/or Dry sealing boxes

- Feed boxes

- Sector clamps

- Quick coupling sector rods

- Plastic sectors

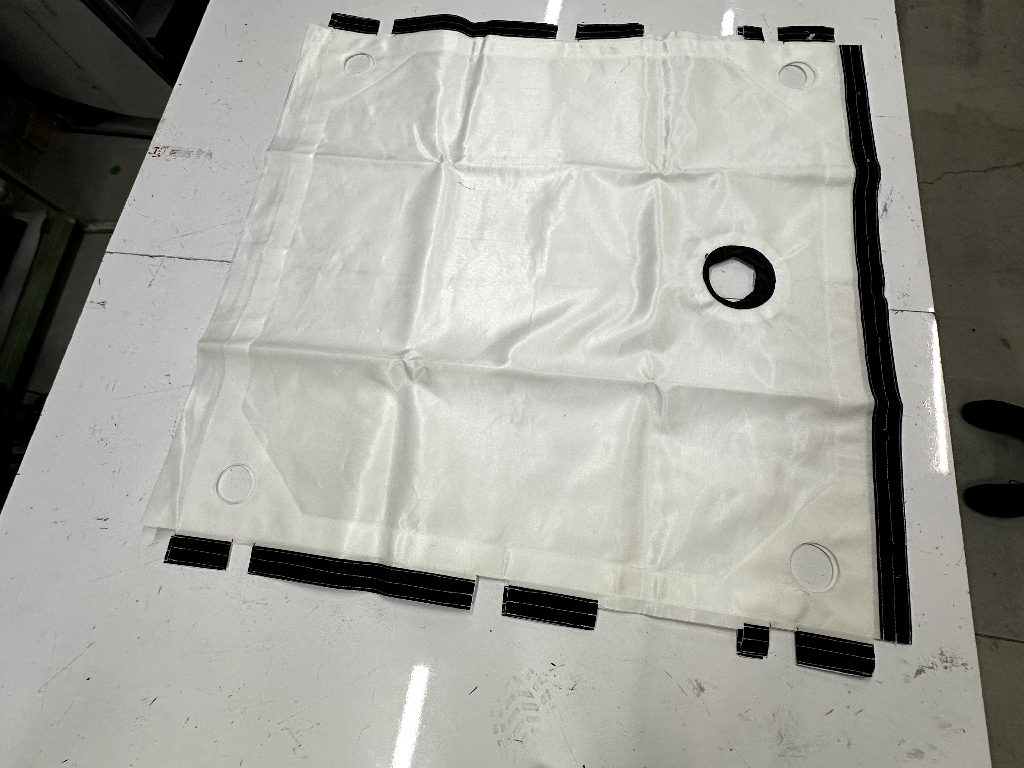

- Filter media (Filter bag and Press cloth)

- Main shaft

- Agitator shaft with replaceable blades

- Ceramic coated basin

-

Filter press

- Filtering plates

- Filtering screens

- Plate handling mechanism

- Valves

- Hydraulic system components

-

Belt filter

- Belt

- Filter fabric

- Tensioner

- Rollers

Slide title

Escreva sua legenda aquiButton

Slide title

Escreva sua legenda aquiButton

Slide title

Escreva sua legenda aquiButton

Slide title

Escreva sua legenda aquiButton

Slide title

Escreva sua legenda aquiButton

Slide title

Escreva sua legenda aquiButton

Slide title

Escreva sua legenda aquiButton

Slide title

Escreva sua legenda aquiButton

Slide title

Escreva sua legenda aquiButton

Slide title

Escreva sua legenda aquiButton

Slide title

Escreva sua legenda aquiButton

Slide title

Escreva sua legenda aquiButton

WEAR PROTECTION

Brasfelt® WP, a division specialized in solutions against wear, applies the most advanced technologies in coatings for hydraulic and pneumatic transport pipes, necessary where severe operating conditions cause significant losses due to abrasive wear in pulp and waste lines, increasing the cost operation of mineral processing plants.

Materials such as cast basalt, high alumina ceramics, silicon carbide and others extend the life of the pipelines, eliminating unscheduled downtime for corrective maintenance.

Learn more about our products on our communication channels or by calling us directly at comercial@brasfelt.com.br

Slide title

Escreva sua legenda aquiButton

Slide title

Escreva sua legenda aquiButton

Slide title

Escreva sua legenda aquiButton

Slide title

Escreva sua legenda aquiButton

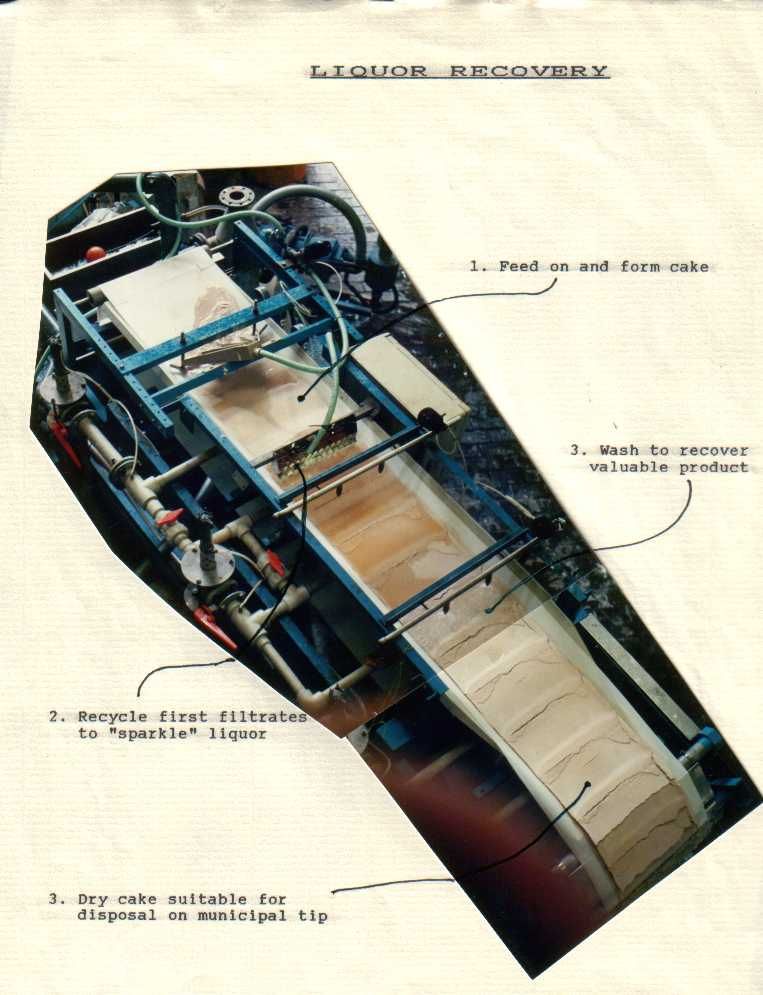

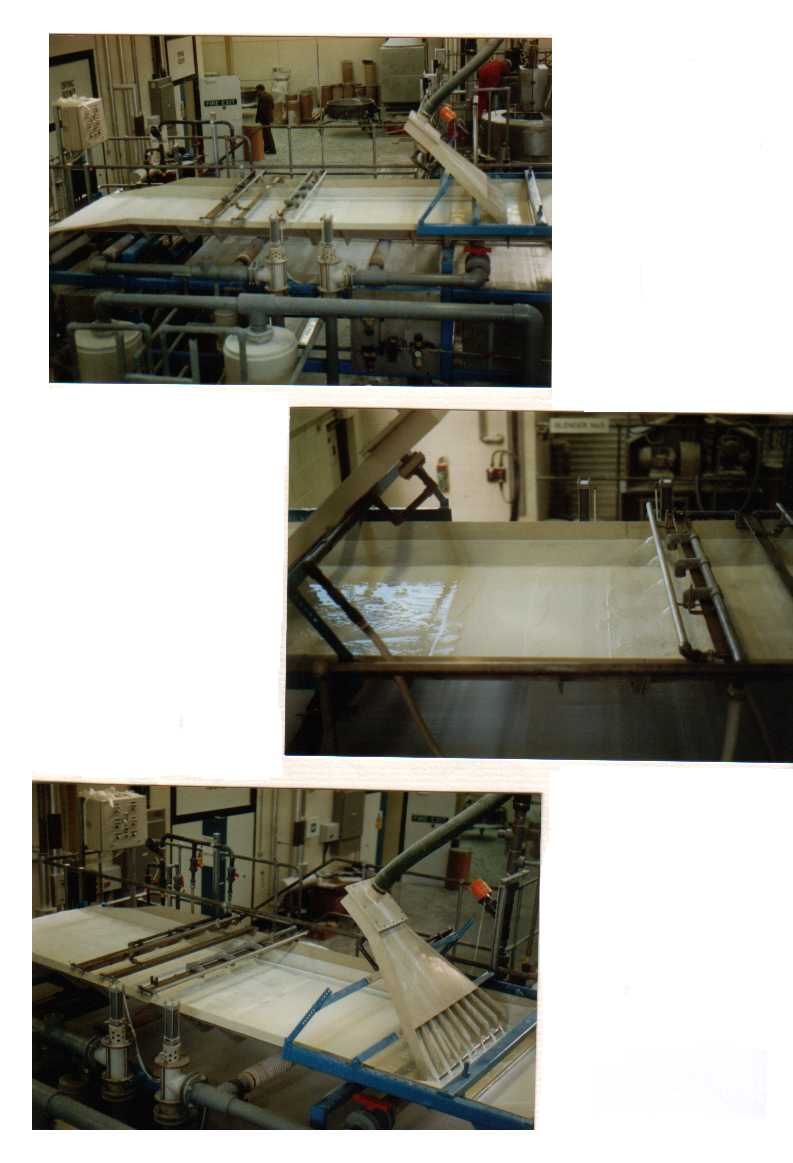

BELT FILTER

BRASFELT Horizontal Vacuum Conveyor Filters are preferably used for filtering thick materials, mainly in processes that require high productivity, combined with the need to wash the cake for greater filtrate recovery.

They can be configured efficiently, both for counter-current washing systems and for washing in the same direction.

Slide title

Escreva sua legenda aquiButton

Slide title

Escreva sua legenda aquiButton

Slide title

Escreva sua legenda aquiButton

Contact

+55 (31) 3194-4700

brasfelt@brasfelt.com.br comercial@brasfelt.com.br

Rua Lecy Gomes Barbosa, 180 - Jatobá, Belo Horizonte/MG, CEP: 30664-004

Site map

Who we are

Clients

Products

Utilization

Services

News

Desenvolvido por Gálata Tecnologia - Tecnologia para Site ©