News

By wellington

•

March 24, 2025

BRASFELT, a specialist in solid-liquid separation processes and a national leader in the supply of Vacuum Disc Filters for iron ore processing operations, has completed the delivery of two more Vacuum Disc Filters, model BRASFELT BF-90.4, each with a 40 m² filtering area. These devices will be used to filter iron ore tailings in Minas Gerais, reinforcing our position as a reference in the supply of filters for tailings in the mining sector. 🚀 What makes our filters unique? ✔️ Technology: Developed to offer maximum efficiency in the tailings filtration process. ✔️ Durability: Components designed to withstand the high wear caused by the tailings. ✔️ Operational benefits: Greater physical availability, reduced operating costs and increased production per filtering area. We remain committed to delivering innovation and results that make a difference for our customers!

March 17, 2025

White January White January is an annual campaign dedicated to raising awareness about mental and emotional health. Created in 2014, its goal is to promote reflections on the importance of taking care of the mind, combating taboos related to psychological disorders, and encouraging practices that improve well-being. Why January? January marks the beginning of the year, a period when many people are more inclined to make plans, evaluate their lives, and think about changes. This context facilitates openness to conversations about mental health and self-care. Main objectives of White January: • Encourage self-care: Raise awareness about the importance of recognizing one's own emotions and seeking professional help when necessary. • Break stigmas: Reduce prejudices associated with therapy, mental disorders, and discussions about emotional health. • Promote healthy environments: Encourage companies, schools, and communities to create spaces that prioritize mental health. White January is a reminder that taking care of the mind is just as important as taking care of the body.

March 17, 2025

Dear customers, Brasfelt thanks you for your trust and partnership throughout this year. Together, we have achieved great accomplishments, and it is thanks to you that we continue to innovate and offer the best in our products and services. We wish you all a Christmas full of peace and joy and a New Year filled with success, health, and achievements. May we continue to grow and strengthen our partnership in 2025! With gratitude, The Brasfelt Team

By wellington

•

December 16, 2024

In 2024, BRASFELT reinforced its commitment to high performance technical solutions by completing another outstanding project in the iron mining segment. To meet the demands of a solution against wear from one of the largest companies in the iron mining sector, we deliver more than 320 linear meters of straight pipes and 40 pieces for flow changes (bends, tees and pipes), in diameters DN14", 18" and 20". All components have been flanged and coated with basalt, an advanced solution from our WP (Wear Protection) line, designed for applications in high-wear environments. This coating ensures greater durability and strength, even in the most challenging conditions, highlighting our ability to meet the industry’s most demanding requirements. Our commitment is to always be at the side of our customers, offering customized solutions that drive the success of their projects. We take this opportunity to congratulate our technical team for the dedication and excellence in yet another high-level delivery! Together, we turn challenges into results! 🚀

By wellington

•

December 2, 2024

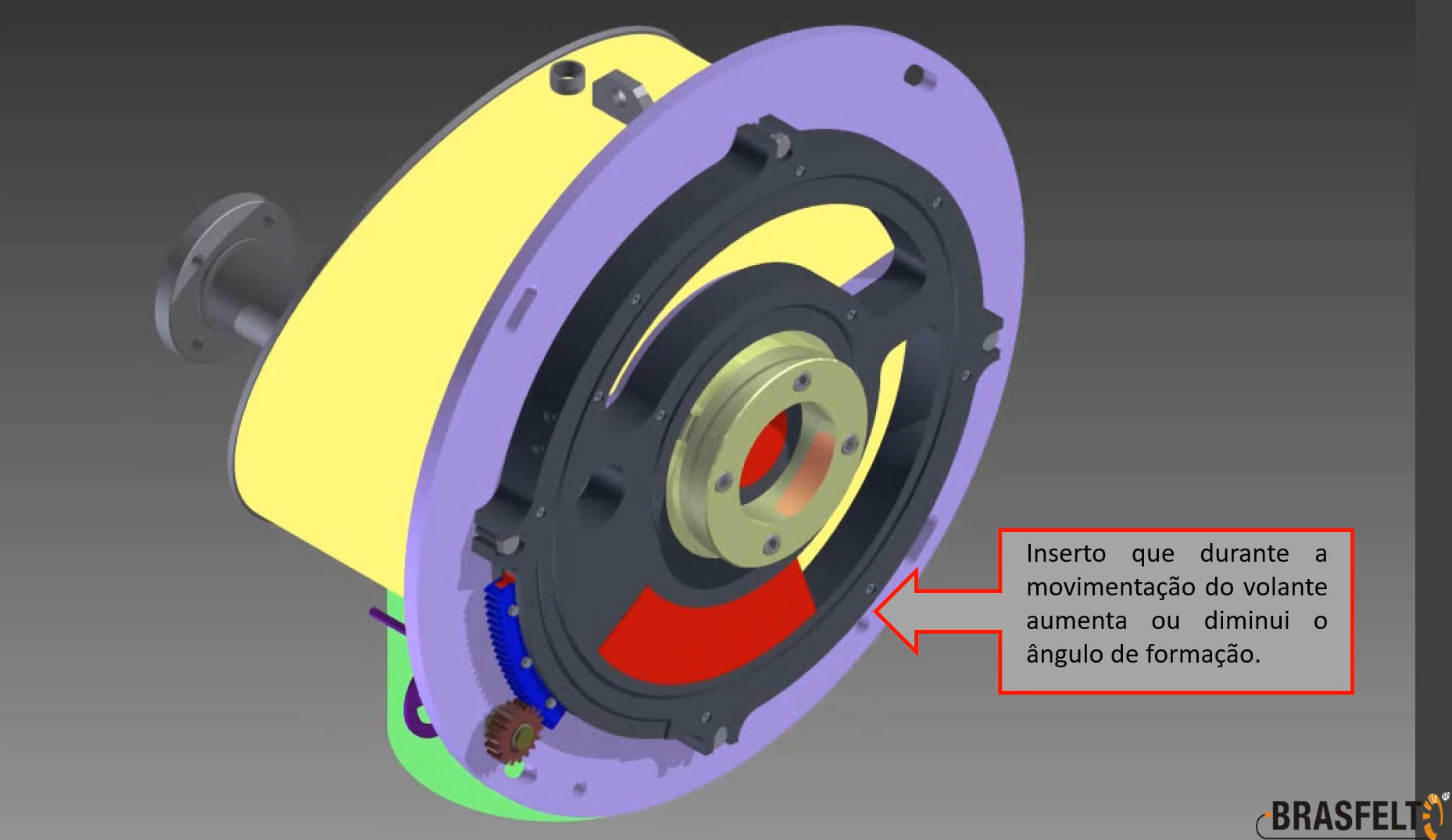

BRASFELT Variable Head: ideal for dynamic process adaptations. Introducing the BRASFELT Variable Head, an innovation developed by BRASFELT to revolutionize the filtration process in Vacuum Disc Filters. With a design focused on efficiency and adaptability, this system allows the pie forming area to be adjusted dynamically without the need to stop operation. This flexibility is achieved thanks to a movable plate, regulated by gears, and an external adjustment shaft to the Variable Head. The BRASFELT Variable Head (Patent BRASFELT PI0705919-1) has the following advantages: Rapid response to process demands: The variable angle of the forming zone allows a better adaptation of the filter to the process demand and/or to the characteristics of the pulp in terms of density, solid concentration and increase or decrease in cake thickness, as described below: Maximum training area: the opening of the training area is as large as possible, increasing the training time. Minimum training area: the opening of the training area is as small as possible, reducing the time of training. An association of these two situations with a suitable rotation of the filter, which will be defined according to the process characteristics of the moment, will allow an optimization between the highest possible production for the expected humidity. Reduced downtime and simplified, ergonomic adjustment: Allows the opening of the pie-forming area to be changed at any time while the filter is still in operation, meaning that the filter does not need to be stopped to change the opening of the forming zone, keeping the opening of the drying zone fixed; This innovation reaffirms BRASFELT’s commitment to excellence, always focused on custom development, using specialized engineering, reinforcing its position as a solid-liquid separation solutions company.

By wellington

•

November 25, 2024

BRASFELT is helping to revolutionize gold ore tailings filtration with the pioneering use of Vacuum Disc Filters, breaking paradigms and overcoming industry challenges by standing out against other traditional filtration technologies for this type of material. The process involves gold tailings pulp from cyclonation, where one part is directed to a thickening phase before going into the Vacuum Disc Filter, while another part is sent directly to the equipment. In this way, the smaller size fraction is added to the larger size fraction and promotes an efficient filtration process of this final mixture. Our client’s confidence in BRASFELT’s expertise in solid-liquid separation was essential for us to apply our knowledge to select the most suitable filtration technology for the project, including laboratory tests conducted at the BRASFELT facility. This innovation reaffirms BRASFELT’s performance beyond the manufacture of equipment, with a customized development approach that covers from laboratory tests to technical meetings with the design, process, operation and maintenance teams of each customer. This specialized work ensures high performance solutions, shaped to meet the specific needs of each operation 🔧 BRASFELT - Innovation that turns challenges into results, promoting new possibilities in ore filtration.

By wellington

•

November 4, 2024

BRASFELT, the national leader in solid-liquid separation, had the honor of conducting a specific training for operation and maintenance of Vacuum Disc Filters for a large customer in the iron mining sector. This training was designed to improve the technical skills of operation and maintenance teams, highlighting the importance of specialized knowledge in maximizing the efficiency and performance of equipment. During the training, we cover in detail the theory of filtration, the principles of operation of vacuum disc filters and the main aspects related to operation and maintenance. We emphasize identifying common problems that can be found in the field, as well as sharing good operation and maintenance practices and the latest innovations developed. The exchange of knowledge provided by this training is fundamental, as it allows us to always be aligned with our customers' needs and to develop tailor-made filtering solutions. The practical approach included case studies and presentation of BRASFELT technology differentials, reinforcing our commitment to excellence. With more than 30 years of experience in the market, BRASFELT stands out in offering complete solutions for concentrate filtration and waste treatment, encompassing all stages, from conceptual design to supply of equipment and peripherals involved. This training is an important step in our mission to share our experiences, ensuring more efficient and sustainable operations in the mineral sector.

By wellington

•

October 21, 2024

Did you know that renovating your Shielded Sealing Box can generate a significant cost reduction compared to buying a new one? BRASFELT, the original manufacturer of Vacuum Disc Filters, offers a complete and reliable service that guarantees high level performance. What is offered: Expert report with issuance of inspection report, detailing the necessary services and parts to be exchanged. Replacement of the used roller with a new one, ensuring the reliability of the refurbished Case. Rigorous quality testing, ensuring that the reworked component meets the required standards. Complete documentation of the services performed, providing transparency of the reform carried out. Guarantee of the reform, bringing security to the client. With the renovation done by BRASFELT itself, it is possible to maintain the performance of your equipment and save in a smart way. Talk to BRASFELT and understand how to start this retirement services partnership!

By wellington

•

September 2, 2024

The Vacuum Disc Filter is widely used in various sectors of mining, standing out for its high productivity and low operating cost. Its robust and efficient design makes it an essential choice for demanding filtration processes. The filter discs are divided into sectors, responsible for giving clothing to the filtering elements, also known as filter bags. It is in these elements that, by acting vacuum in the open area of the sector, the pie is formed. At BRASFELT, we develop our own projects of the main models in the market sectors, such as BRASEC0906 for 9-foot disc filters and BRASEC0636 for 6-foot disc filters. Our sectors, manufactured in thermoplastic material, are designed to maximize filtration performance by reducing pressure drop and increasing vacuum efficiency. This results in a significant increase in production and reduction of the final moisture content of the product. In addition, BRASFELT Sectors are manufactured nationally and have excellent mechanical resistance and erosive wear, combining increased performance with a low cost of acquisition compared to other options available on the market. Another differential is the superior ergonomics of our Sectors, which are significantly lighter than traditional models manufactured in metal or other materials, facilitating the process of assembly and disassembly in the field. 💡 Contact us to find out how BRASFELT industries can optimize your filtering process and deliver significant gains for your operation.

By wellington

•

August 2, 2024

BRASFELT Ltda, national leader in solid-liquid separation in iron mining, reaffirms its prominent position in the supply of vacuum disc filters, with more than 250 filters supplied and installed, in a wide range of customers in Brazil and Chile. With more than 30 years of experience, BRASFELT offers complete and customized solutions for the filtration of concentrates and waste treatment, covering, from conceptual design, the supply of equipment and peripherals. Our equipment is robust and easy to operate, providing significant gains, with greater physical availability, lower operating cost and higher production per filter area. In addition, the filters are designed to resist abrasive and erosive wear, ensuring the reliability and durability that only BRASFELT offers.

By wellington

•

July 29, 2024

The Filtration Laboratory of Brasfelt Ltda has a specialized team and a complete structure for technology selection, equipment sizing and evaluation of filtering parameters. We are prepared to perform bench tests of the main filtration technologies for pulps, sludge and tailings. We have the following technologies for bench test: -Leaf-Test - simulates the operation of Vacuum Disc Filters; -Büchner funnel - simulates the operation of filter-mat; -Labo - simulates the operation of Filter-Press.

By wellington

•

July 15, 2024

BRASFELT/FRACCAROLI & BALZAN: Innovative Solutions for the Mining Industry and Beyond! BRASFELT/FRACCAROLI & BALZAN filter presses are high performance and reliable equipment used in solid-liquid separation, covering a wide range of applications in various segments. During the process, the solids are recovered in the form of cake, while the filtrate, with low solids content, is directed according to the specifications of each application. In mining, they stand out for the efficiency in drying fine tailings, but their versatility goes far beyond, because they can also be used in the filtration of the beneficiation product. In addition, filter presses have a wide range of applications, from steel and metallurgical to fertilizer; from agricultural inputs to effluent treatment plants (ETE’s) and many other areas. At BRASFELT, we understand that each client has specific needs. Therefore, our filter presses are designed taking into account all the characteristics of the material to be filtered and the process. To this end, in addition to engineering, we also have a R&D sector and a laboratory with first-rate equipment, as well as pilot press filters for field tests at customer facilities, if and when necessary. Therefore, we are able to participate in all phases of development of our customers' projects and contribute to the selection of the best equipment for each application, ensuring operational excellence. If you are looking for a technical partner for solid-liquid separation solutions, please contact us!

By wellington

•

June 17, 2024

BRASFELT considers that maximizing the availability of assets to increase production is the main objective of the processing units. That’s why we focus on protecting equipment pipelines with a variety of solutions, thus avoiding unscheduled maintenance. The basalt coating is a product originated from volcanic rocks, which are melted at 1300ºC and molded in different formats, such as pipes, bricks and special parts. The result is a material with excellent hardness, resistant to abrasive, erosive and corrosive wear. It is ideal for use in severe operations, including the transport of iron ore and tailings. We supply pipes and parts coated with basalt and ceramic, aimed at different types of application.

By wellington

•

June 3, 2024

Innovation in the BRASFELT Bearing: Simplified Fixation and Cast Design for Greater Efficiency! In our relentless pursuit of excellence, we are pleased to introduce innovation in the Main Bearing of the BRASFELT Vacuum Disc Filter, a key component in these equipment. OPTIMISED FIXING - Promotion of simplified maintenance: Previously, the design of the BRASFELT bearing had a set welded with threads at the bottom base for fixing the upper saddle. However, due to the events of maintenance and replacement of bushings of the bearing, for which it was necessary to remove the screws, there was wear on the threads and locking the screws, scenario that eventually required complex interventions to perform new drilling in the field. With our new solution for the BRASFELT bearing, we modify the design in favor of a simplified fastening with bolts and nuts. Now, simply remove the bottom nuts for complete screw extraction, facilitating the maintenance process and reducing equipment downtime. 100% FUSED DESIGN - Ergonomic Gains and Efficiency: In the previous design, the bottom of our bearing was composed of a cast piece welded to a carbon steel cradle. This application of solder to the casting eventually resulted in unnecessary additional weight. With the new solution adopted for the BRASFELT bearing, we replaced the lower assembly with a 100% cast piece, resulting in the elimination of the weld application and, consequently, reducing the weight of the assembly. In addition to reducing the weight of the set, which ensures better ergonomic conditions for maintenance, the new design promotes an optimized weight distribution, favoring the durability of the equipment. These improvements reinforce our commitment to quality and continuous improvement of our products, ensuring a more agile and effective maintenance for our customers!

By wellington

•

May 3, 2024

Exploring New Frontiers in Ore Filtration: Introducing the BRASFELT Pilot Plant At the forefront of innovation in mineral filtration, BRASFELT presents one of its projects: the BRASFELT Pilot Plant. Developed as a versatile and effective solution for pilot-scale filtration of iron ores, non-ferrous ores and other materials, this pilot plant represents a significant breakthrough in the field of filtration technology. Using Vacuum Disc Filter technology, with a filter area of 40m², which allows to achieve production capacity of up to 120 tons per hour, the BRASFELT Pilot Plant offers a range of applications in mining. From its use in small scale plants to define solid-liquid separation processes to its application as a practical and compact solution for miners with lower demands, this pilot plant is truly versatile and effective. An important milestone in this journey of innovation was its first deployment in one of the largest iron mining companies in Minas Gerais. During a period of 24 months, the BRASFELT Pilot Plant was leased and used for tests in the treatment of flotation tailings of iron ore, in order to define dry disposal processes (Dry Stacking). This pioneering experience has demonstrated not only the effectiveness of technology, but also its potential to transform industrial practices and collaborate on environmental sustainability. BRASFELT is committed to continuing to drive innovations in ore filtration. With the BRASFELT Pilot Plant, we are prepared to lead the way towards a more efficient, sustainable and responsible future for the mining industry.

By wellington

•

April 29, 2024

Brasfelt Ltda, the national leader in solid/liquid separation in mining, recently completed the supply of four 120 m² vacuum disc filters for a large mining company located in Espírito Santo. With more than 30 years of experience in the market, BRASFELT offers complete solutions for the filtration of concentrates and tailings treatment, from the conceptual design to the supply of the equipment and peripherals involved. The filters provided by BRASFELT have advanced filtering technology, generating operational gains, with greater physical availability, lower operating cost and higher production per filter area. In addition, these filters incorporate technologies to protect abrasive wear, combined with the reliability of Brasfelt products.

By wellington

•

April 18, 2024

As part of this special tailings edition, International Mining Editorial Director Paul Moore talked to Eustaquio Barbosa , Director of Operations at Brasfelt Ltda , based in #BeloHorizonte , Brazil. #Brasfelt manufactures equipment for solid/liquid separation and is the leader in the Brazilian market in #vacuum disc filtration for #ironore while also continuously developing products and solutions for the #filtration of other mined products as well as offering filtration solutions for other industries. Barbosa told IM: "Brasfelt emerged in 1993 as a reseller of filter fabrics and other products produced by Tamfelt Oy, a Finnish company. The business evolved naturally and, due to a lack of local production, started a cooperation with a Norwegian company called Hydralift. Brasfelt then acquired the rights to produce vacuum #discfilters locally, which became the first ones produced in Brazil and were first sold to Vale ’s Kobrasco plant, part of its Tubarão operations, in 1998. After that, Brasfelt modified its solutions and offering so that it could best fulfil the necessities of the local market, including the right price level. The result is that today Brasfelt filters are stronger and allow for higher production and longer operation cycles, consequently decreasing the costs of operation and maintenance. Therefore, Vale and other companies started to acquire Brasfelt filters in Brazil and in Chile, so that Brasfelt became a market leader in those countries." He adds on why disc filters are so suited to Brazilian iron ore tailings #dewatering : "The choice of a filter depends on multiple factors, but one of them is the size of the solid particles. For extremely fine materials, the natural choice is filter presses. But for not so fine particles, the natural choice is disc filters. The main operational difference between them, is that filter presses do not have a continuous cycle (they operates in batches) and also the productivity (tonnes per hour per square meter) is lower than that of disc filters. So the use of disc filters in iron ore tailings, which requires high production, was a break in the paradigm that stated disc filters are not suitable for this application. The content of sand really affects how the equipment will perform. Due to this challenge, Brasfelt made some innovations in its disc filters, such as the application of ceramic lining in more vulnerable parts and replacing the filtrate tubes from HDPE (High Density Polyethylene) to polyurethane. These innovations allowed the equipment to be resistant to the sand content of the #tailings ." #futureofmining #tailingsmanagement #futureoftailings #tailingsdewatering

By wellington

•

March 11, 2024

Brasfelt, aiming to raise technical quality and answer doubts of its customers, received, on February 7, the visit of the technical team of CMP - Compañía Minera del Pacífico S.A. On the occasion, presentations were held on the Brasfelt Vacuum Disc Filter and innovations developed and already applied in our equipment. We went through the entire factory, showing a filter to be delivered to the company and that, at that moment, was still with us. CMP has been our customer for over 15 years and has 9 BRASFELT filters in operation.

By wellington

•

March 8, 2024

Today, March 8, we pay tribute to all women, who fought and still fight, with courage, so that their achievements remain untouched. No woman should be judged, discriminated against or disrespected for their choices, whatever they may be. We wish you all a Happy International Women’s Day!

By wellington

•

February 26, 2024

Seeking to improve and optimize the filtration processes, Brasfelt Ltda has developed a head with removable top for the vacuum disc filters. This head makes it possible to change only the top (bottom of the head) that is the zone most affected by wear during the operation of the vacuum disc filter. This option allows inspection and maintenance of the equipment more quickly, as well as ensuring lower maintenance cost, since it allows only the most worn item to be replaced. Benefits of the removable top head: Enables faster and safer maintenance; Lowers maintenance cost with raw material and labor. Brasfelt is always investing in innovation and development of its products. For more information, see our experts: E-mail: comercial@brasfelt.com.br Tel/ Phone: +55 (31) 3194-4705 www.linkedin.com/company/brasfelt-ltda www.facebook.com/brasfelt www.brasfelt.com.br

By wellington

•

February 2, 2024

Brasfelt Ltda, the national leader in solid/liquid separation in mining, has just supplied vacuum disc filters to a large mining company in Minas Gerais. They are equipment with 100 (one hundred) m² of filter area, which will compose the new waste segregation project in the mine’s Fase1.

By wellington

•

January 15, 2024

O uso das placas de desgaste BRASFELT é uma estratégia eficaz para reduzir os custos operacionais de máquinas e equipamentos industriais, bem como aumentar a sua disponibilidade física. Fabricadas com uma combinação de aço carbono, borracha natural e pastilhas de cerâmica de alta alumina (teor mínimo de 92%), as placas de desgaste BRASFELT incorporam as mais modernas tecnologias de materiais. A presença de uma camada de borracha natural, com dureza de 60 SHORE-A, adiciona um componente resiliente à peça, enquanto a cerâmica de alta alumina eleva a sua resistência à abrasão, garantindo uma proteção excepcional contra desgastes: uma solução ideal para a proteção de ativos industriais.

By wellington

•

December 19, 2023

For the filtration simulation with Vacuum Disc Filters, Brasfelt performs the bench test called Leaf-Test . This methodology can reliably represent what happens with Vacuum Disc Filters in industrial filtration. Interested companies can send the samples to be filtered to our headquarters in order to carry out this procedure. Recently, we also developed the Leaf-Test Portable, which consists of taking this equipment to the customer, in a compact way, to perform the test in its dependencies. Thus, with the execution of the Leaf-Test, we were able to find and define the best filtering conditions for Vacuum Disc Filters. Leaf-Test allows simulating the main variables that may occur in the field, such as: Rotation speed of the filter; filter fabrics; training and drying time; pressure and vacuum flow variation; variation in pulp densities; Use of auxiliary filtration reagents.

By wellington

•

December 9, 2023

Brasfelt reminds everyone that December is the month of awareness about two serious issues: skin cancer and HIV. Both are diseases that can be prevented with simple measures, but still cause many deaths in Brazil and worldwide. Skin cancer and HIV are diseases that can affect anyone, regardless of age, gender or sexual behavior. Therefore, information and prevention are fundamental care to be observed. This December, be part of this campaign. TOGETHER WE CAN MAKE A DIFFERENCE!

By wellington

•

December 4, 2023

Brasfelt aims to raise the technical quality of the process, operation and maintenance teams of its customers, promotes training and workshops to replicate the good practices that must be implemented in vacuum filtration. On 11/24/2023 we held the 3rd class of training, Vacuum Disc Filters - Process, operation and maintenance, for the waste filtration maintenance team of the Brucutu plant of VALE. In this training, which is conducted in a dynamic way, the technical and practical aspects that must be applied in the field to ensure performance and service life of the vacuum disc filters are presented.

By wellington

•

November 27, 2023

BRASFELT has filter elements (fabrics) for all wet filtration processes. We manufacture bags for vacuum disc filter and blankets for filter press. These filter elements are manufactured with the aim of obtaining the best efficiency regarding retention, productivity, durability and, consequently, the best cost-benefit. All these factors are directly linked to the filter fabric. We have a wide range of fabrics for the manufacture of filter elements, which are selected through laboratory tests, case by case according to the customer’s need.

By wellington

•

November 17, 2023

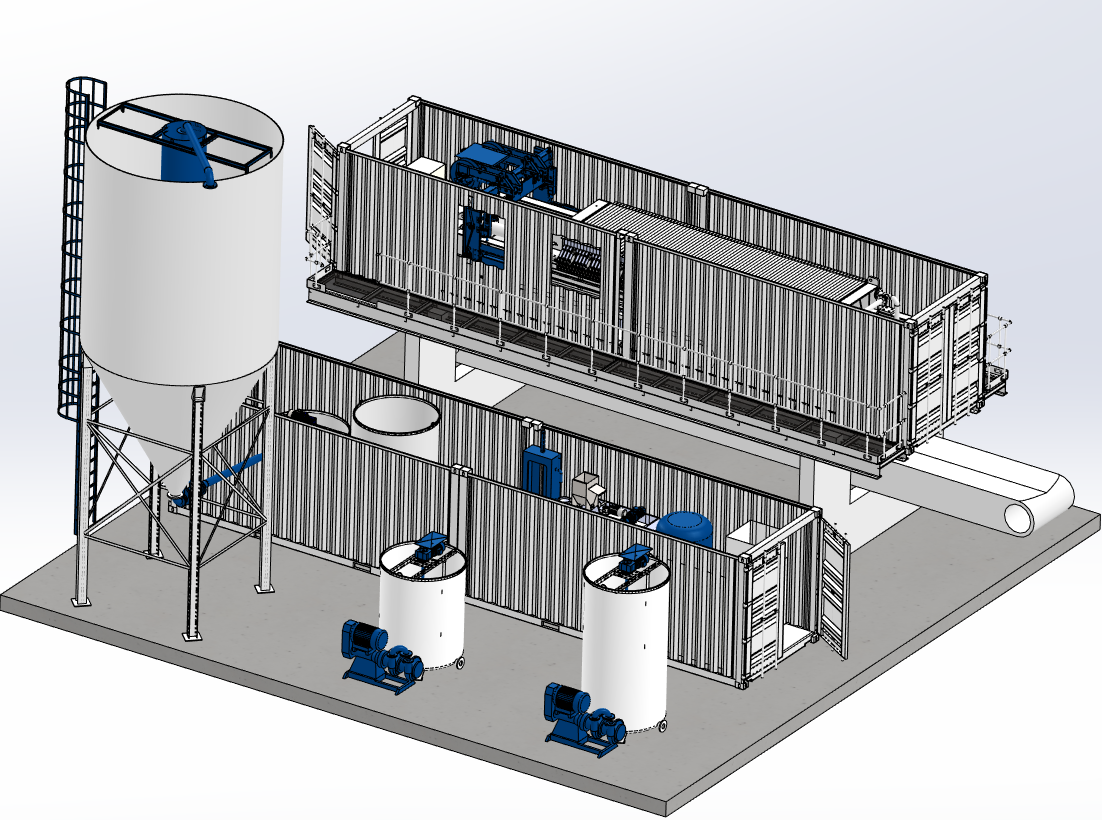

Dam disposal - Brasfelt Ltda, in partnership with Fraccaroli and Balzan S.p.A., has been working on the development of pilot filtration plants, in order to assist its customers in planning, design, operation and implementation of filtration projects in general and especially tailings. The pilot plants are presented in modules, on a smaller scale, with high productivity filters and encompass all the peripheral equipment necessary for filtration, such as thickener, homogenization tanks, pumping of plant feed, conveyor etc. Each plant is designed to meet a representative fraction of the filtration and serves as a real dimensioning parameter of CAPEX and OPEX for each project.

By wellington

•

October 31, 2023

The treatment of tailings is the ideal and economically viable solution for the replacement of the use of dams, besides enabling the recovery of existing residual ore. Recently, Brasfelt Ltda provided 14 Vacuum Disc Filters for a large iron mining of Minas Gerais, with 140m² of filter area per filter, for tailings filtration. With 30 years of experience in the filtration and Vacuum Disc Filter market, BRASFELT offers complete solutions for the treatment of tailings, ranging from conceptual design to the supply of equipment and peripherals involved in the process. The dry disposal of the treated waste allows the reuse of the pits, increases the recovery of water in mineral processing and, in some cases, the marketing of waste as a by-product, in addition to avoiding the risks inherent in dams.

By wellington

•

October 25, 2023

Brasfelt Ltda presents the NT21 EASY POWER SOLUTION device, which was developed to assist the maintenance of disc filters, when there is a need for repositioning the main axis (tree). This device allows this activity to no longer be performed manually and favors routine maintenance, such as changing bags and sectors, with absolute safety. The NT21 is designed to run on a low-power pneumatic motor using the customer service compressed air line. The pneumatic motor can be easily blocked instantly by simply closing the quick-release valve on the panel accompanying the equipment. Easy to install, no filter intervention is required. Brasfelt Ltda sells the NT21, also installing it in filters that are already in operation. The NT21 can be integrated into new equipment, thus facilitating the maintenance of filtration. We are available for clarification and technical visits.

By wellington

•

September 4, 2023

Seeking to improve and optimize more and more processes in Vacuum Disc Filtration, Brasfelt developed the Head with Variable Formation Zone. This head allows a variation in the formation zone of the cake, without disassembly of the head, allowing the operator to instantly define the time of formation depending on the characteristic of the material to be filtered. This variation allows an instant control of the thickness of the pie and as a consequence better control of moisture and production. Brasfelt Variable Forming Angle Vacuum Inlet Head - Patent PI0705919-1 The Variable Forming Angle Vacuum Inlet Head is an item patented by Brasfelt. Brasfelt Ltda is always looking to improve and develop new products. Benefits of the Variable Head: -Allows direct, fast and objective action, without disassembly of the equipment. -Change in training time without changing the drying time. -Change in the formation time without changing the rotation speed of the filter.

By wellington

•

July 30, 2023

In order to expand the knowledge of the operation, maintenance and process teams of our customers, Brasfelt Ltda held on Monday, 07/24/2023 a workshop for operation and maintenance of BRASFELT vacuum disc filters. In order to answer the doubts of professionals, this training addresses in a didactic and objective way the vacuum filtration process and the good practices that must be adopted during the operation and maintenance of the disc filters to ensure a high production, with quality and reliability. Being of interest, Brasfelt Ltda leaves its communication channels open for future scheduling, this and other training that its specialized team is able to offer.

By wellington

•

July 27, 2023

Due to its high productivity and low operating cost, the Disc Filter is used on a large scale in the mineral filtration process. The discs are divided into Sectors, whose function is to support the filter elements that make solid-liquid separation, in addition to conducting the filtered liquid to the collector tubes. Brasfelt Ltda has several models of sectors in its product catalog, especially the BRASEC0906 for 9 feet Disc Filters and the BRASEC0636 for 6 feet Disc Filters.

By wellington

•

July 17, 2023

Brasfelt Ltda invests in the evolution of its team, providing excellent service to its partners and customers. Last June, the training on Ore Treatment was carried out by Eng. Antônio Abdo Júnior, from 3a1 Inteligência Mineral Ltda., expanding the vision of the Brasfelt team beyond filtering and trainingto better understand and meet the demands of each client in the particularities of their processes. Brasfelt and its entire team thank 3a1 Inteligência Mineral Ltda. for their shared knowledge.

By wellington

•

July 7, 2023

Brasfelt and Fraccaroli & Balzan present their modular press filtration plant, type "plug and play". It is a complete filtration unit, mounted in containers, designed to reduce the time and costs of a standard installation. It is basically composed of two containers: one houses the filter press and the other houses the auxiliary equipment.

By wellington

•

June 26, 2023

BRASFELT received on 05/04/2023 the technical team of Fraccaroli & Balzan, to fulfill a schedule of technical training in press filtration. In the opportunity were carried out laboratory tests, lectures for sizing filters of the Discovery, Columbia and Enterprise line, sizing of thickeners of the Oasis and Wonder line. Brasfelt your best choice in press filters.

By wellington

•

June 6, 2023

Seeking to maximize the efficiency of its product, Brasfelt – leader in the filtration market – innovates once again in vacuum disc filters, developing plate picking. Developed in accordance with regulatory standards NR-12 and NR-17, it is a system that prevents the accumulation of materials on the deflector plates, by means of a manual or automatic drive, which can be electric or pneumatic, that shakes the plate regularly.

April 10, 2023

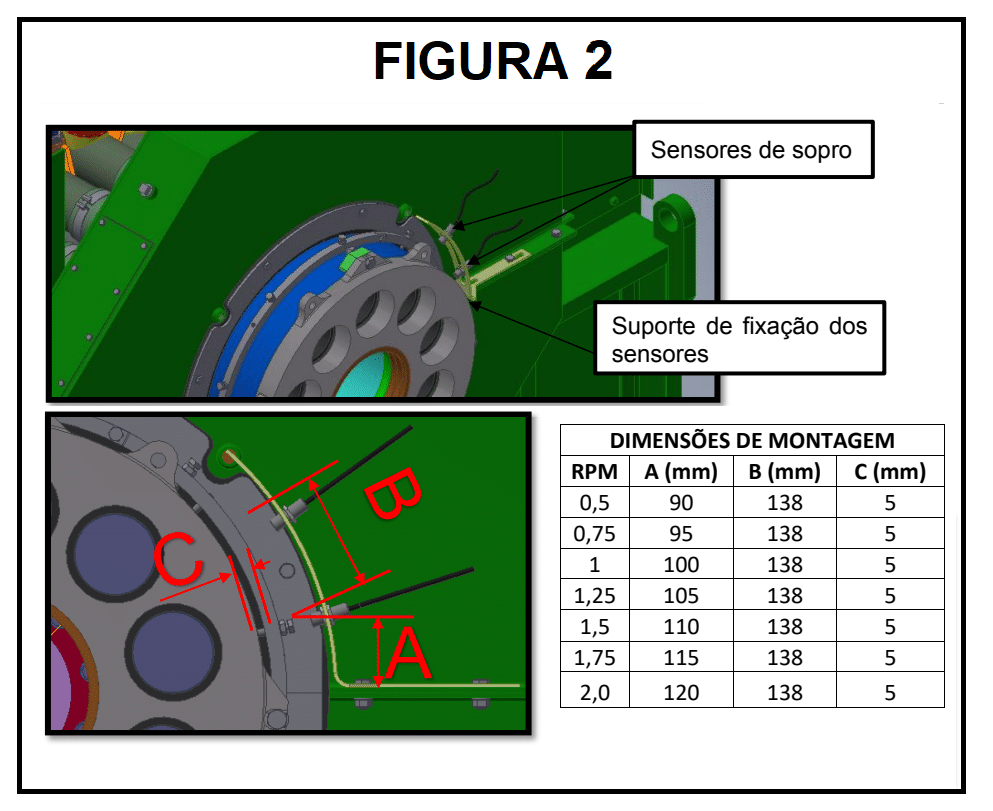

The importance of blowing regulation in Vertical Vacuum Disc Filters. The filter operating cycle ends with the cake unloading, which is done by means of a “blow” of compressed air, in a short period of time, with an approximate pressure of 1.0 to 2.0 bar. The blow occurs with the magnetic signal generated by the approximation between the sensor and the indicator bumps in the center of each filtrate tube. The correct adjustment of the moment of blowing causes the detachment of the cake to occur in the correct position in relation to the deflector plate and the discharge box, also preventing the filtering element from touching the edge of the box or the deflector plate at the time of discharge. The correct adjustment of the blowing, maintains the synchronization of the sensor and the blowing collar, which must be done, in a BRASFELT filter of 8'10", according to the following steps: 1st step (FIGURE 1) - Assemble the position collar on the drive hub (in some models the position indicators are fixed directly on the main shaft transition hub), according to the positioning indicated in the figures below. 2nd step (FIGURE 2) - Assemble the sensor and sensors fixation support according to the positioning indicated in the figures below.

By wellington

•

March 31, 2023

Technical and commercial cooperation agreement Fraccaroli & Balzan Brasfelt Ltda, a national leader in filtration systems based in Belo Horizonte, and Fraccaroli & Balzan, a traditional filter press manufacturer based in the city of Verona, Italy, announce to the market that they have entered into a technical and commercial cooperation agreement to supply press filters in Brazil. The union of these two companies will bring to the Brazilian market the best technologies and solutions for solid-liquid separation systems in which the use of filter presses is indicated, in mineral processing, waste recovery and effluent treatment plants installed in Brazil.

Contact

+55 (31) 3194-4700

brasfelt@brasfelt.com.br comercial@brasfelt.com.br

Rua Lecy Gomes Barbosa, 180 - Jatobá, Belo Horizonte/MG, CEP: 30664-004

Site map

Who we are

Clients

Products

Utilization

Services

News

Desenvolvido por Gálata Tecnologia - Tecnologia para Site ©